- NASA SPACE SHUTTLE SPECIFICATIONS PORTABLE

- NASA SPACE SHUTTLE SPECIFICATIONS PROFESSIONAL

- NASA SPACE SHUTTLE SPECIFICATIONS SERIES

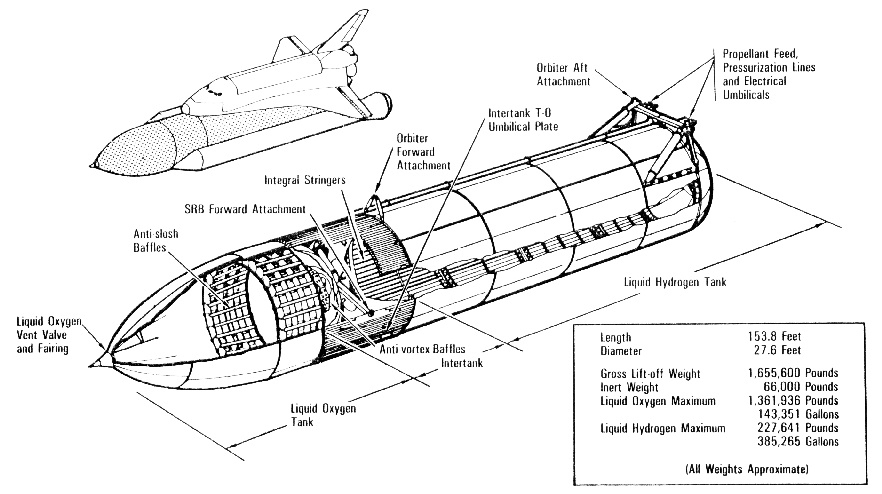

The Manager, Space Shuttle Program, on a Space Shuttle PRCB Directive (PRCBD). Processed in accordance with NSTS 07700, Volume IV - Book 1 and dispositioned by Or deviation and the rationale to justify its consideration. The CR must include a complete description of the change, waiver Interest of the SSP to change, waive or deviate from these requirements, an SSPĬhange Request (CR) shall be submitted to the Program Requirements Control Board When it isĬonsidered by the Space Shuttle program element/project managers to be in the best Specifications, and other SSP documents insofar as they pertain to pyrotechnics.Īll elements of the SSP must adhere to these baselined requirements. NSTS 07700, but takes precedence over element project documents, CEI Item (CEI) specifications and other documents. This specification is the source for the expanded definition of pyrotechnic requirementsįor all elements of the Space Shuttle system which are documented in Contract End Gained in prior space programs is applied to the pyrotechnics in the SSP. The ET was 47 m (153.8 ft) tall and 8.4 m (27.6 ft) in diameter, and contained separate tanks for liquid oxygen and liquid hydrogen. Pyrotechnics throughout the Space Shuttle and further requires that the experience The Space Shuttle external tank (ET) carried the propellant for the Space Shuttle Main Engines, and connected the orbiter vehicle with the solid rocket boosters. Maximum commonality of hardware, technology, practices, and procedures relating to Program documents of more general nature and use. Shuttle pyrotechnics for use at the various levels of activity and minimizes the inclusionsĪnd repetitions of the specialized requirements peculiar to pyrotechnics in other This specification provides a single, comprehensive document pertaining to all Space

Program requirements controlled by the Manager, Space Shuttle Program, areĭocumented in, attached to, or referenced from Volumes of NSTS 07700. Subsequently controlled by SSP management. Interface agreements, and system capabilities shall be documented, baselined, and J), NASA SPACE TRANSPORTATION SYSTEM: SPACE SHUTTLE SYSTEM PYROTECHNIC SPECIFICATION (1)., Efficient management of the Space Shuttle Program (SSP) dictates that effectiveĬontrol of program activities be established. NASA remains very satisfied with the quality of Aerovent’s products and the units are performing to specifications.Ĭall Markair, Inc.NSTS 08060 (REV.

NASA SPACE SHUTTLE SPECIFICATIONS PROFESSIONAL

The detailed report states “all work was performed in strict accordance with specifications and in a professional manner.”įor the past five years, the Aerovent units have been operating during landing and recovery of the space shuttle fleet. The painting and inspection process took a total of six days. Together, they reviewed the specifications and inspected everything from surface preparation to measuring dry film thicknesses (DFT) on each fan. Aerovent provided a full-time QC person to work with the NACE inspector. Aerovent hired a NACE certified company out of Pompano Beach, Florida to perform the inspections and to provide the certified reports.

NASA SPACE SHUTTLE SPECIFICATIONS SERIES

In addition to the extensive documentation and testing requirements, NASA STD-5008 required a Certified National Association of Corrosion Engineers (NACE) Inspection of all of the fans. The LEGO NASA Space Shuttle Discovery (10283) set is part of a series of buildable models for adults, offering an escape from everyday life with display pieces. The coating was a white Ameron paint that required sand blasting, an Amerlock 400 primer and an Ameron PSX700 topcoat. The fans were all welded aluminum construction fabricated to fit the existing shrouds. The motors were severe wash down duty with stainless steel housings, shafts, and hardware. Quality, performance, and delivery were very critical requirements of the specifications.Įach of the three units required sixteen (16) 30″ DDP condenser fans and four (4) 16″ DDP pre-cooling fans for a total of sixty (60) fans. The seacoast environment required special materials and coatings for corrosion protection. The fans and coils had to bolt to an existing shroud and provide substantially higher performance. The existing cooling air supply units were not performing to specifications and required new fans and coils.

NASA SPACE SHUTTLE SPECIFICATIONS PORTABLE

TCF Aerovent supplied twenty (20) panel fans for each of three (3) of these portable air conditioning units. One of the fleet support systems is a portable air conditioning unit. Once the orbiter lands at the end of a mission, the Shuttle Landing Fleet of vehicles keep systems on the orbiter operating while it progresses through checkout stages. As each orbiter returns to earth from its final voyage, it is greeted by products designed and sold by Markair, Inc. Contents 1 Description of main components 1.1 Orbiter Vehicle 1.2 External tank 1. 2010 is the final year for NASA’s aging space shuttle fleet. Each Shuttle was designed for a projected lifespan of 100 launches, or 10 years, operational life.

0 kommentar(er)

0 kommentar(er)